Jeddah South Thermal Power Plant — Civil Works Package

The project includes onshore civil and building works for Package #1 includes Power block No. 1 and No. 2 including BOP area, and for Package #3 includes Administration building area.

1) The scope of civil works involves foundations, structures, cable trench, duct bank, pipe laying, drainage and sewage works.

2) The scope of building works involves earthworks, reinforced concrete works, masonry works, painting, water proofing, tiles and flooring, doors and windows and miscellaneous metal works.

The main items of work comprise:

Excavation : 431,430 m3

Backfilling : 146,230 m3

Concrete works : 207,660 m3

Rebar : 21,760 ton

Structural steel : 620 ton

uPVC pipes, dia. 150mm — 500mm : 9,580 lm

GRP pipes, dia. 600mm — 1400mm : 4,250 lm

Jeddah South Thermal Power Plant — Seawater Intake Pumping Structure

The project includes Engineering, supply, installation, operation and maintenance of cofferdam, dewatering and shoring for the construction of pumping structure in dry, Earthworks such as excavation, disposal and backfilling, Construction of bottom slab, internal and outer walls, top slab and other concrete structures, Dismantle of dewatering and shoring facilities, Foundations for overhead cranes, Supply and installation of steel access platform and Removal of cofferdam.

The main items of work comprise:

Structural excavation : 270,700 m3

Structural backfilling : 211,324 m3

Sand filling : 14,070 m3

Concrete works : 54,588 m3

Epoxy coated rebar : 10,770 ton

Cast in situ piles (600mm dia) : 114 nos.

Sheet piles for cofferdam : 4,430 ton (16,260 m2)

Deep well pump for dewatering : 135 nos.

Saudi Arabia — Shoaiba II Power Plant: S/C for Daelim for Power Area

The project includes civil and building works in the power area.

The main items of work comprise:

A. Package 3

Civil and building works for power block area I including: GTC foundations,

TR foundations, piperack and sleeper foundations, local control and electrical building and air compressor building.

B. Package 7

Civil and building works including HVAC, fire fighting works for BOP area II including:

— HRSG Foundations and HRSG electrical building

— Emergency diesel generator building

— Crude oil plant building

— Central control building

— R.O. desalination building

— Fuel oil storage tanks

— Distillate storage tanks

— Fire water pump house

— Fire water tanks

Major Quantities:

Excavation : 64,385 m3

Backfilling : 230,740 m3

Concrete : 31,500 m3

Structural steel: 150 ton

Reinforcement: 1,360 ton

Saudi Arabia — Yanbu: Aramco NGL Terminal

The project includes works in the facilities collectively referred to as the Yanbu Export Refinery Project (YERP) Terminal Facilities Package (SP-7) which consists of three, non-adjacent areas, within the existing plant.

The main items of work comprise:

A. Red Sea Refining Company Metering Area & Marine Operation Area.

Custody Metering Systems: The custody metering system will be provided for the export products, with new metering skids

Product Slop System

Ship’s Slop System

Instrument Air/Plant Air System

Contaminated Vapor Blower Package

New RSRC Control Room

Sanitary Sewer System

Fire Protection System

Combustible Gas Detection

Drain System — Potentially Contaminated Storm Water

Plant Nitrogen System (PNS)

Site Preparation and Development

New Security Fencing

Automation Facilities

Communications

B. Berths (71 & 72) Facilities (offshore):

New Red Seas Refining Company Product Pipelines: Demolish 4 existing mothballed pipelines (32″ pipeline propone vapor, 30″ pipeline butane recovery, 24″ bunker fuel and 12″ black diesel) totalling 4.0 km.

Installation of same quantity of new RSRC product pipeline (two 30″ Diesel, 30″ Gasoline, 24″ Gasoline recirculation). In addition the project will install 800 meter cantilever extension to the existing trestle. In this over water cantilever, five new pipelines will be installed (18″ contaminated vapor line, 14″ benzene loading, 8″ ship slop, 6″ diesel slop, 6″ gasoline Slop and 3″ benzene slop)

New Tower Cranes: Two new Tower Cranes to be installed, one at each berth, to replace the existing Tower Cranes

New Loading Arms for RSRC Products: Three new RSRC product loading arms to be installed at each berth. A new 16″ Diesel Loading Arm will be installed in the future spot and a new 16″ Diesel loading arm and 12″ Benzene loading arm will replace the two existing mothballed loading arms.

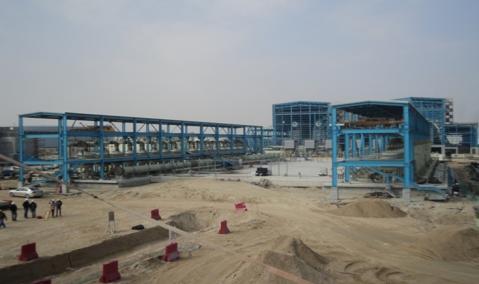

Egypt — Banha Power Plant: Civil Works

The project includes design, furnishing, installation and construction of Civil, Architectural, Electrical and Mechanical works for Banha 750 MW Combined Cycle Project. The project consists of one combined cycle module configured as 2 x 250 MW Combustion Turbine Generator, two Heat Recovery Steam Generators and one 250 MW Steam Turbine Generator.

The main items of work comprise:

1. Site Preparation

2. Piling Works

3. Concrete Works

4. Structural Steel Works

5. Architectural and Electromechanical works for buildings:

— Combustion Turbine Building

— Steam Turbine Building

— Control / Electrical Building

— Circulating Water pump house

— Circulating Water Electrical Building

— Circulating Water Intake and Discharge Structures

— Administration Building

— Warehouse / Workshop Building

— Fire Station, Security Offices and Toilet Facilities

— Underground Piping

7. Underground Electrical Duct Banks

8. Circulating Water Pipes

9. Landscaping and irrigation systems

10. Roads, finish grading and drainage, etc.

Major Quantities are:

Concrete works: 60,000 m3

Structural steel: 3,510 tons

Reinforcing steel: 6,250 tons

Production piles: 17,000 lm (800mm dia.)

R.C. pipes: 1,150 lm (800mm 2,500mm dia.)

Saudi Arabia — Yanbu: Marafiq Seawater Cooling Pipeline Network

The project includes the design, procurement, construction, testing and commissioning of a seawater cooling pipeline network.

The main items of work comprise:

Supply and return seawater cooling pipelines to and from Yanbu Industrial City II together with a spare supply / return pipeline. These pipelines (3 nos.) will each be approximate 5 Km in length and of equal diameter and to be laid in a common trench and will run in the Royal Commission Corridor. The mechanical works consist of valves including isolation (butterfly) valves, air valves and pressure reducing valves.

Electrical works:

Actuators for operation of butterfly valves greater than 600mm diameter together with local cabinet for electrical isolation and connection point for a mobile electrical generator.

Earthing for valves / actuators.

Cathodic protection will be provided for underground and submerged metallic structures.

Major Quantities:

Excavation: 644,105 m3

Structural backfill: 411,763 m3

Backfill around pipes: 126,021 m3

Filter Fabric: 214,632 m2

Concrete (all grades): 34,218 m3

FRP Pipe (dia. 2.8m): 8,964 lm

FRP Pipe (dia. 1.5m): 3,168 lm

FRP Pipe (dia. 1.0m): 1,008 lm

Structural Steel: 63 T

Asphalting: 2,462 m2

Qatar — Halul Island: R.O. Desalination Plant

The project included engineering, procurement, installation, construction and commissioning of a fully operational treatment plant. The plant is fully automated controlled from control room through Honeywell DCS control system, has also a Chemical Lab fully equipped and the quality of the Water is automatically monitored.

The main items of work comprised:

Intake and seawater pump and chlorination system. New sub-sea pipeline for seawater intake consists of HDPE pipes 500 l.m.

Pre-treatment system including chemical dosing and cleaning system.

Seawater Reverse Osmosis desalination system including intermediate tanks and chemical dosing.

Subsea outfall pipe for the disposal of waste brine consists of HDPE pipes 350 l.m.

Post Treatment (Remineralization)

Product Distribution: Two new product storage tanks, transferring pumping station and interconnection pipe to the existing potable water tanks, interconnection pipe to TEPQ and to new control camp.

Auxiliary systems and all the associated electrical, instrumentation and loss prevention.

The provision of all necessary safety equipment.

Civil works intake pump house building, Potable water Tank Compound and New Desalination Plant Building

Main quantities:

Excavation: 21,654 m3

Concrete: 3,483 m3

Reinforcement: 1,665 ton

Various Dia GRE Piping: 2,180 m

Various Dia HDPE Piping: 450 m

Various ABS piping: 1,500 m

Various Dia Valves: 645 m

Cables: 149 km

Tanks (various sizes): 16 Nos

Pumps (various capacities): 39 sets

Saudi Arabia — Yanbu: Marafiq Marine Works

The project includes Engineering, Procurement and Construction of the civil, mechanical and electrical works for the seawater intake facility and associated pumping station, access tunnel, seawater discharge channel and outfall, control building, electrical building, chlorination plant and pump house, workshop and associated utilities, roads and fencing works.

The main items of work comprise:

Dredging: 1,750,000 CUM

Excavation: 83,000 CUM

Rockworks: 152,951 CUM

Reinf.concrete works: 47,000 CUM

Steel structural: 442 ton

GRP pipes (3600/3200/2700&2300dia): 2,345 m

Cladding: 7,000 sqm

Combiwall: 5,280 sqm

Roads: 34,000 sqm

Reinforcement: 8,854 ton

Damietta 500MW Power Plant — Civil Works

The project included demolition and earthworks, concrete and piling works, building works of 1,657 m2 floor area, electrical and mechanical works, mechanical/passive oil separator including pumps, pipes and associated works for successful operation, HDPE pipes 700 LM for sewage network, storm water drainage system, duct banks and permanent plant roads, parking area and paving and fencing.

The main items of work comprised :

Excavation: 65,000 m3

Backfilling: 29,900 m3

Concrete works: 22,100 m3

Reinforcement: 2,991 Ton

Piling works: 1,097 LM

Saudi Arabia — Ras Al-Khair: Desalination Plant

The project includes EPC offshore works comprising 8x4m dia. X 3Km long GRP Discharge pipes with end diffusers, an intake channel comprising of a dredged channel and 2 rock breakwaters 1.4 km long, a seawater intake pumphouse 105m x 75m and the discharge chamber to the pipes (40x20m). EPC for offshore consisting of the ground improvement and backfill across the site of RO and MSF plants. The civil and building works include construction of RO building, RO switchgear building, waste water treatment, chemical dosing building, dissolve air floatation and 2 nos. dual media filters.

The main items of work comprise:

Offshore works:

Rockworks: 515,851 cum

GRP pipes installation: 24,000 m

Dredging: 1,575,791 cum

Backfilling: 813,572 cum

Reinf. Concrete works: 46,683 cum

Sheetpiles: 8,271 sqm

Reinforcement: 6,151

Onshore works:

Earthworks: 432,000 cum

Soil Improvement: 306,590 cum

Reinf. Concrete works: 88,612 cum

Structural steel: 28,000t

U.A.E. — Dubai — Jebel Ali DUSUP LNG Terminal : Construction of Jetty

The project included the construction of DUSUP LNG Receiving Terminal in Jebel Ali Port, containing the connection to onshore grid by 24″ underground pipeline installed by horizontal directional drilling.

The main items of work comprised:

Construction of a Jetty with one Unloading Platform, four breasting dolphins and five Mooring Dolphins. The Island Jetty is built on 102 vertical and raked steel piles. The superstructure is a combination of precast elements and insitu concrete, connected with Walkways and having a small craft landing structure. Cathodic protection was provided for the piles.

Fabrication and Installation of 24 inches high-pressure pipeline in undersea horizontal drilling including all piping from the two unloading arms situated on the 1st Breasting Dolphin, till the tie-in point onshore at a receiving station, as well as procurement and installation for the cathodic protection for the subsea pipeline.

Installation of Loading Arms,

Installation of Gangway Tower,

Mechanical Works for the Jetty Platform and onshore area.

Electrical and Instrumentation works

Major Quantities:

— Concrete works : 5,660 m3

— Reinforcement : 796 ton

— Structural steel works : 162 ton

— Pipeline (24″ dia.) : 1,400 lm

Sidi Krir Power Station — Offshore Works

The project included designing, fabrication, furnishing, delivery to the site, unloading, storage and construction of the offshore cooling water facilities and all services associated with these facilities for Sidi Krir Combined Cycle Power Plant.

The main items of work comprised:

Perform offshore subsurface soil investigation, Bathymetric Survey.

One (1) offshore cooling water intake structure including the chlorine diffuser.

Offshore cooling water discharge structure.

Construction of one (1) GRP intake pipeline from the offshore intake structure to onshore Circulating Water Pump house.

Construction of one (1) GRP discharge pipeline from the offshore discharge structure to the onshore seal well discharge structure interface location.

Warning signs for navigational traffic and associated appurtenances at the offshore intake structure and offshore discharge structure.

Sodium Hypochlorite piping system including anchoring and supports from the offshore intake structure to the onshore circulating water pump house.

Construction of the crossing under summed oil pipelines at intersection location with offshore intake / discharge pipes.

Riprap erosion protection for offshore intake and discharge piping, offshore intake structures, and offshore discharge structure.

Cathodic protection for underground pipes.

Cairo West Power Plant — Units (7) & (8) — Civil Works

The project included design, fabricate, deliver, furnish, deliver to site, store, install, test, start-up, commission, maintain until Taking Over and Acceptance Certificate of: Civil works for Cairo West 2×350 MW Thermal Power Plant, Units (7) and (8).

The main items of work comprised:

Site Development and Underground Facilities

Power Generating Facilities

Auxiliary Facilities

HVAC System

Field Erected Tanks

Lift Stations

Circulating Water Pump House Overhead Bridge Crane

Fire Hydrants, Hydrant Connection Isolation Valves, and Post indicator Valves for Underground Fire Protection Service.

Communication and Paging System

Lightning Protection System and Grounding System

Cables and Raceways, and Underground Duct Bank

Lighting and Power Receptacles

Shoaiba IWPP — Civil, Buildings and Offshore Works

The project included Civil, Buildings and Offshore Works for the Shoaiba IWPP.

The main items of work comprised:

Civil and services works including earthworks, soil improvement, reclamation, foundation of pressure vessels filter and tank, roads & paving, sewage & drainage networks, water and firefighting pipelines, and lighting, etc.

Buildings included the R.O. building, switchgear building, chemical dosing building, air compressor building, chlorination gas and CO2 generation buildings, firefighting pump house, etc.

Offshore works included dredging, extension of discharge channel, shore protection and offshore intake GRP pipeline with riser, etc.

Qatar — Messaieed — Qatalum: Jetty and Seawater Intake

The project included the Engineering, Procurement and Construction of the Import Jetty and the Seawater Intake system for Qatalum Plant within the Mesaieed Industrial City.

The main items of work comprised:

Construction of 300m long Jetty (Berth 8), to handle the import of raw materials, 123m long approach trestle, cat walk, mooring dophin

Provision of two seawater intake systems with pipe-work within a 90m long section of blockwork quay wall (Berth 7) at the stem of the jetty,

Reclamation works for the Qatalum access corridor,

Block paving in the container yard of 11000m2

Shore protection on both sides of the block work quay wall and

Dredging of pockets for berth and quay wall foundation.

Major Quantities:

Concrete : 35000 m3

Rebar reinf. : 5000 mt

Dredging : 77500 m3

Rocks : 57800 m3

Piling (1067mm dia) : 896 l.m. (36 nos.)

Piling (1219mm dia) : 2448 l.m. (96 nos.)

Shoaiba IWPP — Design and Construction of Chimney

The project included basic and detailed design and supply and erection of chimney including necessary temporary works, excavation and foundation works as well as commissioning of systems and equipment. A single wind-shield chimney with three flue gas pipesis having an outer wind-shield of reinforced concrete construction

The main items of work comprised:

— Ladder access system

— Lighting

— Internal lift opening

— Platform Cable trays

— Air craft warning light

Qatar — Ras Laffan: LNG Berth No. 5

The project included the Procurement and Construction of the Marine and Civil Works for LNG Berth 5, as part of Qatar Gas II Development Project.

The main items of work comprised:

Berth abutment (causeway connecting to Berth 5 platform with the existing breakwater)

Loading Platform

Four Breasting dolphins equipped with fenders and quick release hooks (double) with capstan.

Eight Mooring dolphins equipped with quick release hooks (quadruple) and capstan.

Catwalks connecting all dolphins with the platform.

One catwalk connecting the eastern mooring dolphin with the breakwater

Berth 5 Marine Flare Support Structure

Major Quantities:

Rocks : 119,000m3

Precast Concrete Cubes (2 — 5m3) : 5,200 nos.

Piles (1067, 1219 & 1320mm dia.) : 147 nos

Concrete : 8,700m3

Reinforcement : 1,500 T

Stainless steel rebars : 190 T

Installation of catwalks : 13 Nos.

Shoaiba IWPP — Main Civil Works Lot 1, Power Block Area

The project included works for 3x300MW steam turbine power plant.

Main civil works:

earthworks, structural and finishing works, outdoor facilities and underground services.

Building/Structure works:

Construction of various buildings/structures

Foundations for structures

Construction of intake and discharge culverts

Roads and car parking

Booster pump station

Sleepway/bridge structure

Earthing and lighting for buildings

The main items of work comprised:

Major Quantities:

— Excavation : 141,400 m3

— Backfilling : 69,700 m3

— Concrete works : 75,760 m3

— Structural steel : 297 ton

— Reinforcemnt : 12,710 ton

— uPVC Pipes (100mm to 300mm) : 1,425 lm

— Asphalt roads : 44,650 m2

— Heavy duty paving : 128 m2

— Paving : 1,218 m2

YANSAB Olefins Plant 1 — Civil Works at ISBL Area

The project included site preparation and general excavation, earthworks, concrete work, underground piping for the sewers including tie-in points to the existing underground network, underground pressure pipe system including tie-in points to the existing underground network, plant roads and yard paving, civil works related to the underground electrical and instrumentation cable installation.

The main items of work comprised:

Concrete works : 49,152 m3

Reinforcement : 3,480 ton

Pipes (various dia.) : 80,134 lm

Steel works : 403 ton

YANSAB Olefins Plant 1 — Precast Concrete Pipe Racks

The project included supply and installations of main and secondary precast concrete pipe racks with insitu concrete strong points including earthworks and foundations.

The main items of work comprised:

Concrete: 16,247 m3

Rebars: 2,096 m.t.

Rehabilitation of Concrete Structures in Jubail Desalination Plant — Contract No. 2

The project included concrete repair and rehabilitation works for various areas and structures of desalination plants under Phase I & II

The main items of work comprised:

Desalination areas and Power Plant areas.

Boiler area and Power House

Intake Structures including Chlorination area

Power Utility Structures

Seawater Booster Pump House

Cable Tunnels, Trenches and Pits

Outfall Channel and Discharge Outlets

Blending Stations

Pipe Bridges

Road Bridges

Qatar — Messaieed : Revamping for Methanol Plant

The project included engineering design, procurement, construction, installation, testing and pre-commissioning of the methanol plant modifications for the Carbon Dioxide addition project.

The main items of work comprised:

— Buildings for chilled water pump house (steel framed and concrete)

— Concrete foundations for machinery

— Fire and gas protection

— Machinery and equipment

— Pipe works and Instrumentation works

Qatar — Messaieed — Qatofin: Marine Works

The turnkey project included engineering, procurement, construction, commissioning and start-up of a new cooling water system including inlet and outfall pipelines and extension of the container yard.

The main items of work comprised:

Civil works:

— Quay wall of 390 m long including dredging, pre-casting and placing of quay wall blocks, cast in situ capping beam, etc.

— Pump House approx. 20.1m x 36.2 m

— Intake GRP pipelines (2 Nos.) of 1.800 mm dia each (Discharge pipeline and Offshore pipeline system)

— Low Voltage Building

— Reinforced concrete culverts, trenches, etc

— Chlorination tank area

Electromechanical works:

— Installation and commissioning of 6.6 KV cables for seawater pumps, LV/MV transformers, electrical panels, etc.

— PA/GA and fire alarm systems for the pump house area as well as instrumentation and PLC control systems.

— Utility networks including HVAC system.

U.A.E. — Abu Dhabi — Ruwais : S/C for SAIPEM for Jetty Construction

The EPC project included the construction of a steel jetty consisting of trestle, berths, mooring and breasting dolphins, jackets, etc. all supported on piling and together with jetty fittings i.e., fenders, quick release hooks and navigational aids. Also the construction of footbridge and road links to the existing jetty. Dredging of area of two berths and disposal of dredged material. Installation of seawater intake pipeline, offshore intake structure and chlorination pipes. Pipes were layed in dredged trench on gravel bedding and backfilled with suitable material.

The main items of work comprised:

Dredging : 676,770 m3

Piling — (tubular steel piles 1,067mm dia.) : 4,200 lm (196 nos.)

(jacketed piles 1,067mm dia.) : 2,660 lm (152 nos.)

Intake Pipelines (GRP pipes 3,200mm dia.): 1,730 lm

Zawia Combined Cycle Power Plant Project. (Subcontract for Cooling Water Intake Pipework)

The project included cooling water intake pipework for the Zawia combined cycle power plant.

The main items of work comprised:

Dredging of seabed trench for a total length of 390 m and depositing the dredged material at one side of the trench.

Total Volume of Dredging: 148,300 m3.

Installation of four rows of 2600mm dia. GRP pipes in the seabed trench extending approx. 390 m from shoreline.

Installation of 4 nos. pre-cast concrete intake heads.

Backfilling of the trench using excavated material and armor rocks.

Flue Gas Desulphurization for Jeddah Stage IV Plant

The turnkey project included design, construction/manufacturing, testing and commissioning of the main work.

The main items of work comprised:

Civil, Structural & Building Works: including site development, foundations for equipment and structures, construction of seawater chamber, pumphouse and overflow pits, reconstruction of stacks, construction of roads, pavings and fencing, water supply, storm water and sewerage systems etc.

Electrical, Mechanical and Instrumentation Works: including Flue Gas Desulphurization Plant and associated equipment, electrostatic precipitator, cranes and lifts, electrical plant, air conditioning, fire fighting and telephone systems, water transfer system, compressed air station and instrumentation and control facilities etc.

Construction of Berth 37, Jubail

The project included procurement and construction of Berth 37 on west side of the petrochemical quay no. 1 to handle seagoing chemical tankers ranging from 3,000 d.

The berths consists of a concrete main deck supported on tubular steel piles and have an open cellar deck below the main deck, made of protected steel grating.

The main structures of the berth included a loading platform, 6 nos. breasting dolphins, 4 nos. mooring dolphins, an access trestle, 6 nos. catwalks and perimeter road including culverts and retaining walls. Other services and facilities included fire fighting and potable water systems, HVAC system, cathodic protection system, electrical works, cabling, lighting and telecommunication system. Total quantity of piling works: 1536 mt.wt to 80,000 dwt.

The main items of work comprised:

Concrete: 2,900 m3

Rebar reinf.: 517 mt.

Struct. Steel: 602 mt.

Shoaiba Steam Power Plant, Stage II — Phase 1 & 2 (6 x 370 MW)

The turnkey project included the design, supply, construction, installation, testing and commissioning of a 6 x 370 MW units steam turbine power plant.

The main items of work comprised:

Site preparation, soil improvement and site services including landscaping & irrigation, waste water & storm water drainage, evaporation and waste water holding ponds, potable water system and water treatment system, roads & sidewalks, etc.

Buildings and structures including steam generation & power generation buildings, industrial & process buildings, water production and treatment buildings electrical control building, cooling water pumphouse, warehouse, chimney and other buildings and foundation works, etc.

Fuel oil handling system and storage tanks, diesel tanks and water tanks, etc.

Seawater main cooling water pipe work, discharge culverts and channels

Cable tunnels, cable duct banks & trenches, pipe and cable racks, etc.

NGL Project, Damietta Export Facilities, Jetty Construction Works

The project included the design and construction of a loading / unloading facility for LNG carriers including a landing bridge, jetty head, 5 nos. mooring dolphins and 4 nos. breasting dolphins. The structures were constructed on tubular steel piles of 1220-mm dia. and 1520-mm dia, filled with reinforced concrete.

The main items of work comprised :

— access ladders

— mooring rings

— quick release hooks

— steel catwalk etc.

Qatar — Ras Laffan: Liquid Products Berths

The project included detailed engineering, procurement and construction of four berths on gravity structure comprising of common approach jetty and back to back R.C. loading platform, breasting and mooring dolphins and catwalks. The relieving platform is constructed on bored concrete piles.The contract also included construction of a common building, electric substation, fire fighting facilities, navigational aids, oil spill control equipment and lighting amongst other topside installations as well as testing and commissioning of the project.

The main items of work comprised:

Total reclamation: 182000 m3

Concrete works: 194000 m3

Rocks: 497000 m3

Piling eorks (900mm dia): 3900 lm (176 nos.)

Egyptian LNG Project — Marine Facilities Work

The project included dredging, construction of breakwater and construction of marine jetty for the Egyptian LNG project

The main items of work comprised:

Dredging:

Design and dredging of 4 km long channel to a depth of -14m CD.

Dredging of a turning basin to a depth of -13.5m CD.

Disposal of dredged material and maintenance dredging for the turning basin and channel.

Breakwater:

Pre and post dredge survey and dredging of soft clay material below the breakwater and substitution and compaction with suitable material and disposal of dredged material

Design and construction of 800 m long breakwater with rocky materials and precast armour units.

Jetty:

Construction of a marine jetty 2500 m long on tubular steel piles to handle lng carriers ranging from 70,000 m3 to 140,000 m3 comprising of onshore approach ramp and roadway, trestle piles, precast concrete pile cap beams and steel girders modules containing pipe rack and roadway, loading platform, a marine operation platform, 4 breasting dolphins, 5 mooring dolphins and 13 tug landings.

Electro-mechanical works involve installation of process pipings, loading arms, cable trays, wharf fittings, cathodic protection and berthing aid system.

Petrochemical Berth 36 — Offshore Works, Jubail

The project included the construction, takeover of design responsibility of new petrochemical berth to receive tankers of up to 50,000 dwt and be capable to accommodate tankers of up to 80,000 dwt.

The main items of work comprised:

The construction of a berth consisting ofa concrete main deck, supported on tubular steel piles, an approach trestle, six breasting dolphins and four mooring dolphins, and dolphins are connected by means of catwalks. Electrical power distribution, instrumentation for all nonproducts related facilities, berth deck lighting, and HVAC are part of this contrast. All the structures such as approach trestle, breasting and mooring dolphins and loading platform are constructed on tubular steal piles.

Qatar — Messaieed: Topsides Facilities to the Multi Products Berth

The project incuded engineering, procurement and construction of the topsides facilities to the multi products berth.

The main items of work comprised:

Supply and installation of mech electrical topsides works to an existing berth including metering skids and loading arms.

Construction of ancillary administration building, fire station, electrical substation and renovation works.

Associated external access roads and infrastructure.

Removal of existing 24″ dia. Submarine oil pipeline.

Construction of 1 no. Mooring dolphin involving precast blocks and in situ concrete.

Dredging 90,000 m3.

Seawater Cooling System Expansion at Yanbu

The project included engineering, procurement and construction for expansion of seawater cooling supply and return lines to serve industrial growth and to the growth in the steam power generation and desalination plant and to improve reliability of seawater supply in northern sector petroleum area.

The main items of work comprised:

Supply and installation of FRP pipes, including excavation, sheet piling, dewatering and backfilling.

Construction of reinforced concrete chambers, access manhole, outfall structures and thrust blocks.

— Diameter of FRP pipes :3,700mm

— Total length of pipelines :9,050m

The Contract also included 15 KV cables, 1125 KVA secondary unit stations and cathodic protection works.

South Valley Development Project, Sheikh Zayed Canal, Design and Build Branch 3 Pumping Stations

The project included designing and building for the construction of three pumping stations for the branch 3 canal includes all civil, mechanical, electrical and instrumentation works. The major works include construction of main pumphouse with concrete intake and discharge basin, installation of pumping sets, ancillary buildings, guard houses, fire protection system, sanitary facilities, electrical panels, cables and controls, roads, parking areas, slope protection and landscaping.

The main items of work comprised:

The capacity of the pumping stations being as follows:

ps1 : 7 pumps (6 on-duty+1 stand-by) each having a flow rate of 8.68m3/sec.

ps2 : 5 pumps (4 on-duty+1 stand-by) each having a flow rate of 8.68m3/sec.

ps3 : 5 pumps (4 on-duty+1 stand-by) each having a flow rate of 4.34m3/sec.

Shoaiba Steam Power Plant, Stage I — Phase 2 (3 x 350 MW)

The turnkey project included the design, supply, construction and commissioning of additional 2×350 mw power plant units.

The main items of work comprised:

Civil work

Industrial work

Buildings

Offshore facilities

Offshore services

Electro-mechanical works

Upgrade of R.O. Plant and Support Facilities, Jubail

The project included procurement and construction of the expansion to the potable water production capacities at the existing r.o water treatment plant (wtp).

The main items of work comprised :

The upgrade and associated support facilities include raw water supply system, potable water distribution networks, addition of a potable water distribution network and the addition of a potable water pump at the north west station.

The expansion of the r.o. plant include the new installation of three 7,570 cubic meter per day water plants.

The expansion of the existing water treatment facilities will include a new pump station consisting of four pumps, four new raw water wells, four replacement raw water and offsite potable water and brine pipelines.

The scope of work includes all associated civil, mechanical, piping, electrical and instrumentation works.

Fuel Oil Receiving Terminal for Shoaiba Power Plant

The EPC project included a marine terminal for oil tankers ranging in size from 20,000 to 100,000 tonnes with facilities for unloading crude and heavy fuel oil and include the following civil, mechanical, instrumentation and electrical works.

The main items of work comprised:

Piled access jetty, unloading platform, breasting and mooring dolphins, walkways and all associated fittings.

Ancillary buildings including control building, foam pump house, store and electrical substation.

Tanker access telescopic gangway and pedestrian access gangway.

Four hydraulically powered fuel unloading arms and two fuel unloading pipelines with all associated valves; oil slops systems and thermal insulation.

Two flow metering stations and two automatic pipeline samplers.

Oil spill control for the access jetty and unloading platform.

Instrumentation and controls including marine terminal control room equipment, distance viewing, warning lights, speed of approach equipment, weather recording equipment and communications and telephone systems.

Power distribution, protection and control quipment.

Navigational aids including lighted buoys. Total quantitiy of piling works: 1016mm dia steel piles : 8,300lm.

Shoaiba Steam Power Plant Stage I, Phase 1 (3 x 350 MW)

The turnkey project include the design, supply, construction and commissioning of the works for a 3×350 MW power plant.

The main items of work comprised:

Offshore Works, including intake, outfall and shore protection, etc

Onshore Works / Buildings and Civil Works, including pumphouse, cofferdam, industrial buildings, non-technical administration and facilities buildings, roads, bridges and pavements, drainage and water supply network, etc.

Tank farm consisting of 6 nos. fuel oil tanks of 100,000 m3 capacity, 2 nos distilled water tanks of 27,200 m3 capacity and 4 nos. other tanks of 4,500 8,700 m3 capacity together with associated piping, valves and fittings.

Electro-mechanical Works, including substations, power supply & distribution networks, lighting system for buildings, area lightings, fire protection and fire fighting systems, etc.

Construction of Seawater Cooling Pumphouse No. 2, Jubail

The project included the construction of the second seawater cooling pumping plant and auxiliary facilities to meet the demand of water by the industries and increase seawater cooling system capacity at jubail industrial city. The second pumping plant increases a total combined capacity of 101.6 cu.m./sec.

The main items of work comprised:

The works covered under this contract included extension of dredged intake channel and supply channel, pumping plant workshop, head works, electrical equipment building, chlorination plant building and pumphouse. A third standby generator, one boat launching ramp, one vip pier, a workshop substation, a mosque and new control panels to be installed in the existing control building.

Electrical, mechanical and instrumentation works:

Installation, operation, testing and commissioning of eight seawater cooling pumps with associated chlorination equipment, four drum screens, twenty eight headworks sluice gates, chlorination gates and drainage gates. One standby gas turbine generator, electrical equipment and cables, two gantry cranes and one workshop crane.

Chlorination distribution pipework and valves, seawater cooling pump discharge piping. Electrical cabling conduits, fittings, cable tray for lighting, grounding, cathodic protection and fire alarm system.

Also included are surface water drainage, foul water drainage, potable water system, oil water and emergency acid drainage system, treated water irrigation system and oil spill protection system.